INTRODUCTION

Energy Optimization & Boost Solution

Our company developed state of art energy conservation solutions beginning 2002. After more than 18 years of extensive R&D and investments, we have successfully developed the field proved and patented NANO BLOCK ENERGY CONSERVATION SYSTEM with substantial saving range from minimum 15% up to 50% depending on the industry and applications of load required. This unique and patented solution can help to resolve insufficient incoming source and supply issue due to extensive load upgrading and expansion of initial load. It also helps to improve and resolve major power quality issue with this technology and solution.

Our practical solution from harnessing potential energy loss will able to solve substantial energy saving needs by all industry due to acceleration of energy cost globally. Our energy efficiency equipment known as NANO BLOCK ENERGY CONSERVATION SYSTEM can be applied to various type of M&E equipment including UPS, motors, pumps, machines, air compressors, chillers plant, ventilation fans, lighting and other appliances that commonly used in various industry and application mainly factories, office buildings and malls.

We commercialized our ‘Nano Block System’ in small scale beginning year 2018. The area of energy conservation can be applied:

- All electrical equipment users in light or heavy industries

- Insufficient load at premises

Valuing Relationships

Our business model in principle are partnership based on continuous innovation, striking a good and balanced relationship with our clients. We offer to share our ‘Nano Block System’ & empower our business associates to do the same with their clients. We will continue to invest and ensure further product development for our business associate and the clients

urther development undertaken is the ‘Nano Power Panel System’ which comprises ‘Nano Block System’ and ‘Nano Gen System’. The Nano Gen System has proven track record, having extensively used in combination with ‘Wind Turbine’ technologies. The ‘Nano Gen System’ in wind turbine technologies have proven accreditations & certification over many years and been used by most developed countries.

PATENT

3. PRINCIPLES OF NANO BLOCK ENERGY CONSERVATION SYSTEM

Step 1How does the energy loss in circuit?

When a charge Q is moved from one end of the terminal of a battery to another then there is an energy released in the form of kinetic energy of the electrons.

Now some of this energy could be lost in the wire, due to motion of electrons causing jiggling of atoms, thus heating up the material. This effect solely depends on the properties of the material and this is precisely resistance. So, when a current Is passed through a resistor, energy is spent in heating up the wire.

So heat is a form of energy transferred due to temperature difference between 2 points. But is that same concept is applicable in this context as the energy lost in the form of heating the wire

In principal, we do know that an energy loss mainly comes from Joule effect through heat as there will be resistance in conductors.

Power dissipated in a resistor is proportional to the square of the current that passes through it and to its resistance

Formula : P = I²R * Heat (joule)

Joule heating, also known as Ohm’s law heating and resistive heating, is the process by which the passage of an electric current through a conductor produces heat.

How are ions able to conduct electricity?

Electricity is associated with motion of charges. Ions are nothing but those atoms which have either gained or lost one or more electron(s). So, these atoms get charged, as they now hold an extra charge.

Ions thus are charged particles, capable of constituting an electric current. Just like in a gravitational field, the mass moves from a higher potential to a lower potential, similarly, a charged species moves from a higher electric potential to a lower potential, this constitutes a current.

Step 2

Can losses ion be e xchange orreplaced ? Yes

Ion Exchange Resin, Ion exchangers are either cation exchangers that exchange positively charged ions (cations) or anion exchangers that exchange negatively charged ions (anions). There are also amphoteric exchangers that can exchange both cations and anions simultaneously.

Step 3Can the negative ion generate and insert into electric circuit? YES.

Negative ions are abundant in nature, especially on the ocean surface, at the beach and after a storm. They are widespread in mountains and forests in form minerals. These are the following processes acquired in order to constitute the loss.

- Electro chemical Process

- Pyro process.

- Ion insertion and clash process.4. Heat Oxidization process

Mineral compound and other substances formulated in electrochemistry used to remove the heat inside the conductor.

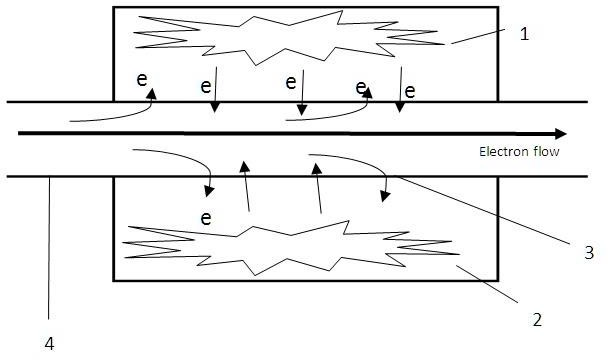

Electrochemical reaction, process either caused or accompanied by the passage of an electric current and involving in of electrons collimations between mineral substance.

Under ordinary conditions, the occurrence of a chemical reaction is accompanied by the liberation or absorption of heat and not of any other form of energy; but there are many chemical reactions that—when allowed to proceed in contact with two electronic conductors, separated by conducting wires—liberate what is called electrical energy, and an electric current is generated.Conversely, the energy of an electric current can be used to bring about many chemical reactions that do not occur spontaneously. A process involving the direct conversion of chemical energy when suitably organized constitutes an anion charge. A process whereby Anion charges energy Mixed directly into electric cable via pyro pressure method and ionizations energy feed trough negative ion power from mineral compound for compression and saturation process.

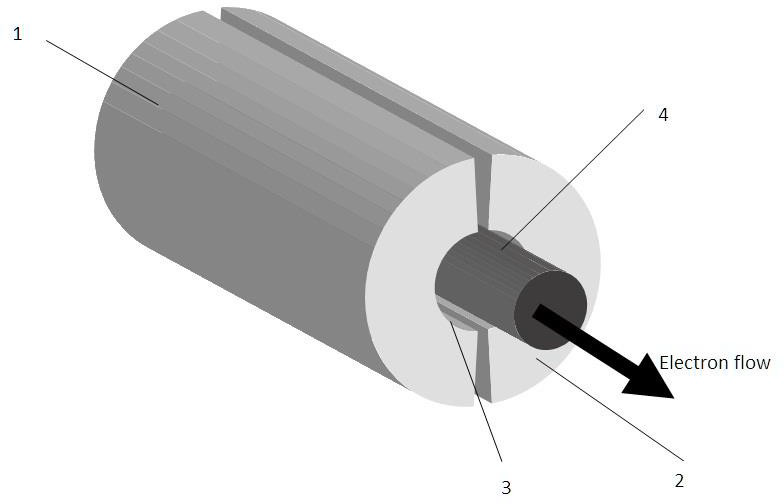

5. NANO BLOCK SYSTEM

Design and Ion Force I nsertion Method

Cable wounding with appropriate block calculation and cable length using coulomb law; inverse, proportional with distance law.

5.2 Nano Block Panel Installation

Cable wounding with appropriate block calculation and cable length using coulomb law; inverse, proportional with distance law.

5.3 Features in Nano Block Panel

5.4 Ampere Saturation Process

By virtue of their combined chemical energy, the products of mineral compresses process tend to react spontaneously with one another, reproducing the substances that were reactants and were therefore, able produce cool current in downstream circuit. The heat current will be extract via Nano Zinc Oxidation process.

Nano Power Panel System can be used to solve problem of conventional power output ‘reduction methods’ with a simple solution by applying our Nano Power Panel System’ onto any conventional electrical current flow. This present invention can be used to save energy, maximize energy conservation and suppress escape of current via Coulomb law thus allowing cool-current to flow through the power cables. The use the system enables long term savings as the present invention has a lifespan of about 3-5 years and would not need to be replaced throughout its lifespan compared to conventional methods.

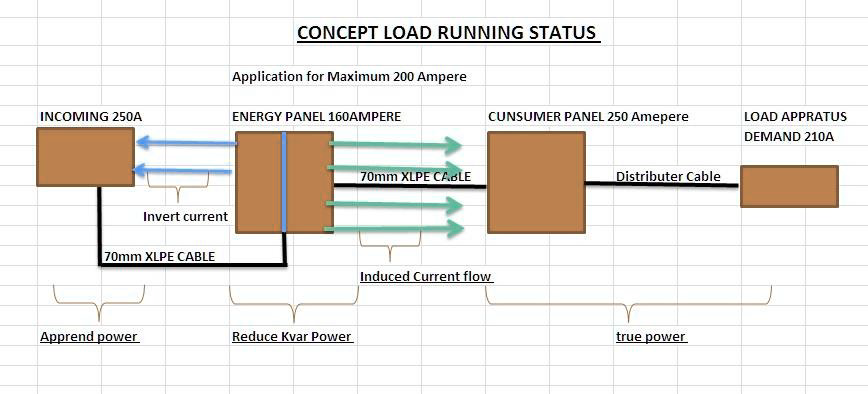

‘Nano Power Panel System’ analogy with gases (similarly to the analogy between water and electricity flow) allows electrical particles, or the electrical charges, could be "compressed" to obtain an increased energy density when it is "pushed" one over another one by a strong coulomb charge .This result in a new way of energy charged and reducing flow of existing load by coulomb charge driven by capacitor, according to downstream load compensation level of energy horizon. Power factors from source are maintained and not manipulated. Explanation of compressions process below:

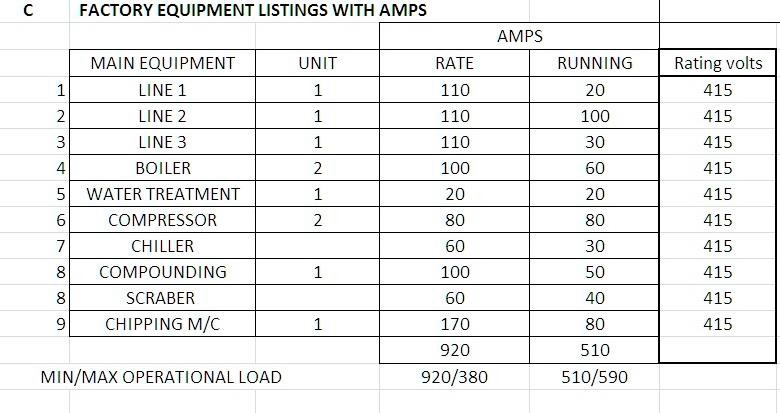

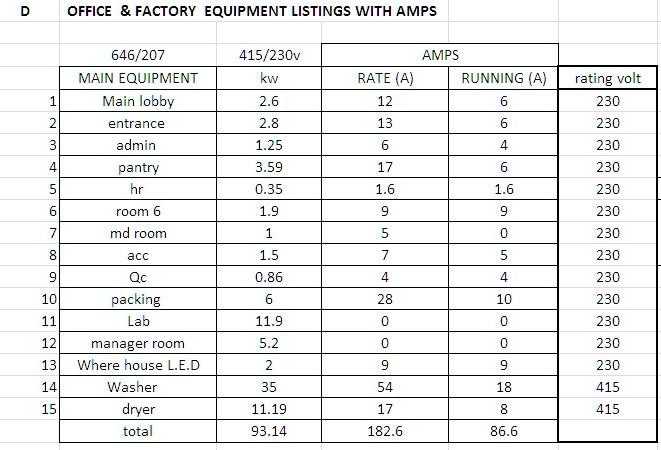

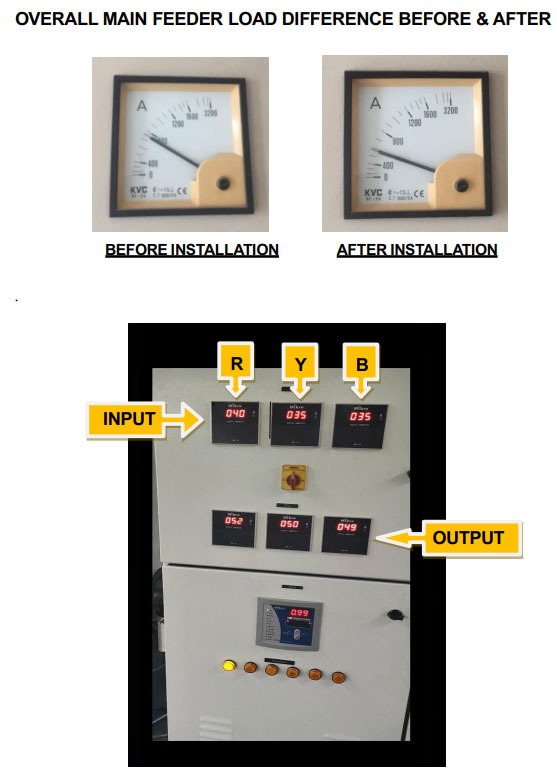

6. PILOT PROJECT AT JR ENGINEERING & MEDICAL (M) S.B

Installation & Performance

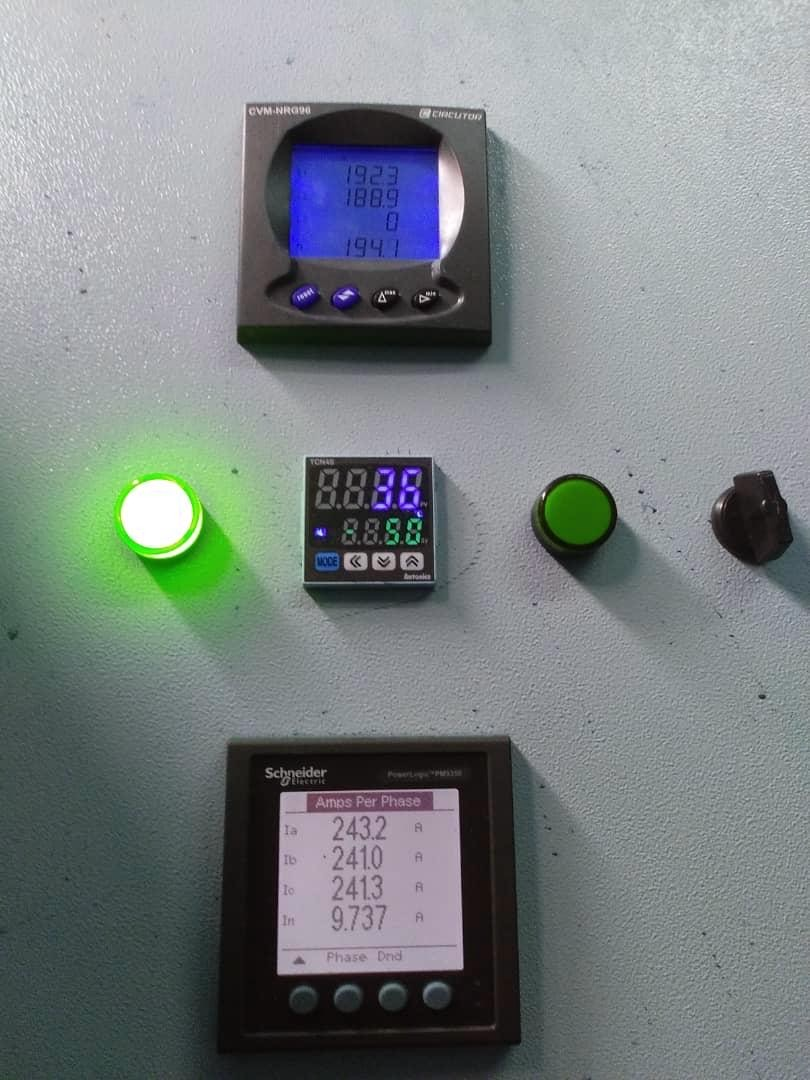

6.2 Exploring Load and Savings

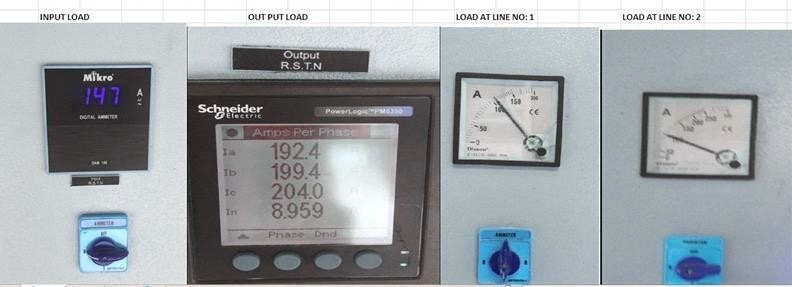

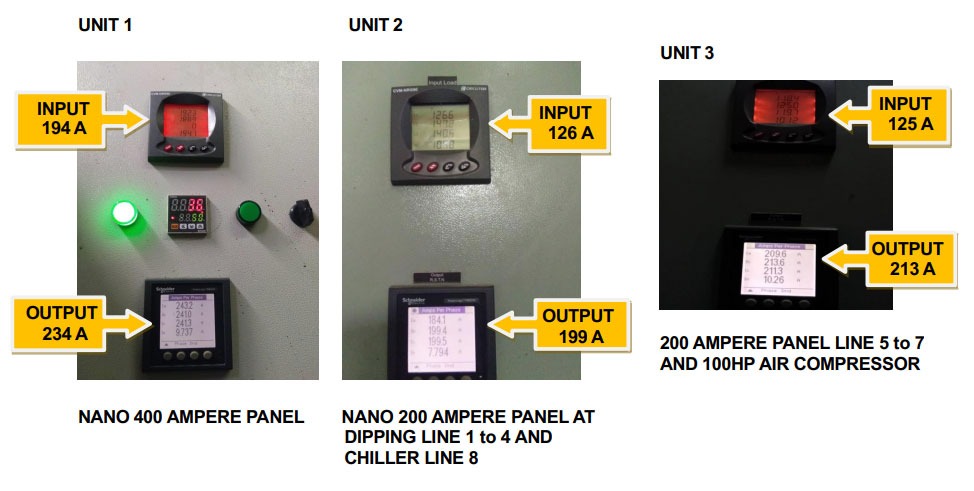

Input Load from TNB Grid 400 Amps

This factory currently had shortage of incoming power for full operation. After installation of Nano Panels, they able run to boost the current incoming to run full operation. Previously, they require to switch equipment and process due to maximum of 400 Ampere. Current Output load increased to 590 Ampere.

Input Load From TNB 60 Amps

This factory currently had shortage of incoming power for full operation. After installation of Nano Panels, they able run to boost the current incoming to run full operation. Previously, they require to switch equipment and process due to maximum of 400 Ampere. Current Output load increased to 590 Ampere.

Power Booster

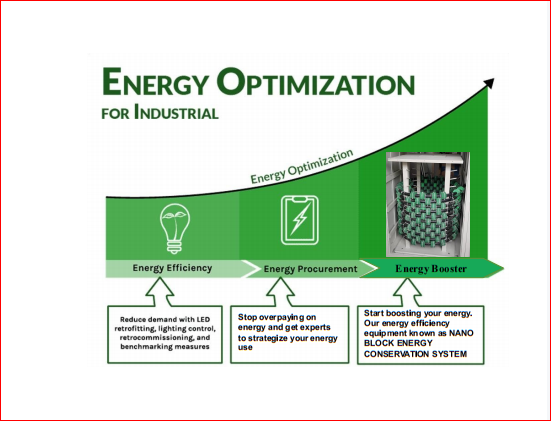

Energy Optimization

PRODUCT INTRODUCTION NANO BLOCK

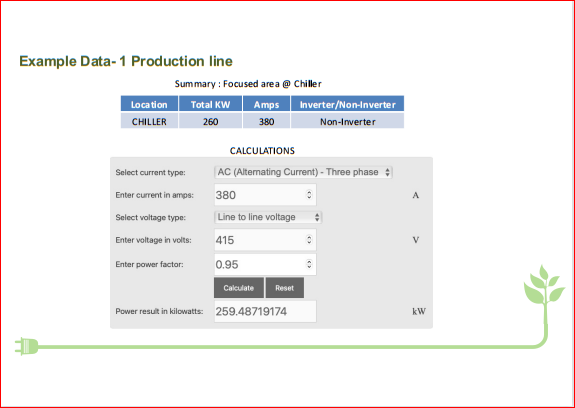

PRODUCTION LINE

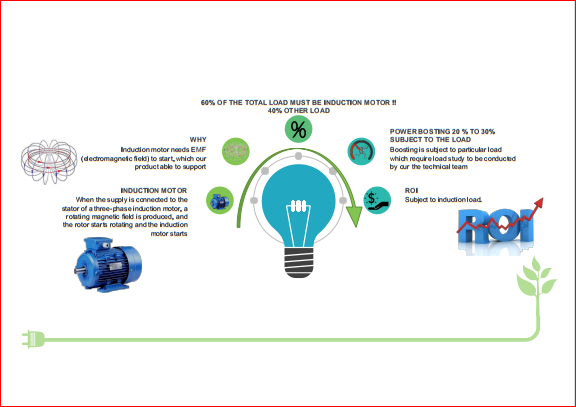

ROI

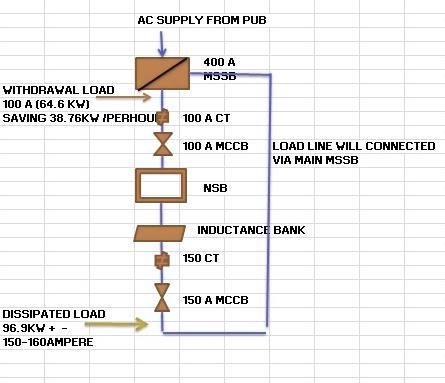

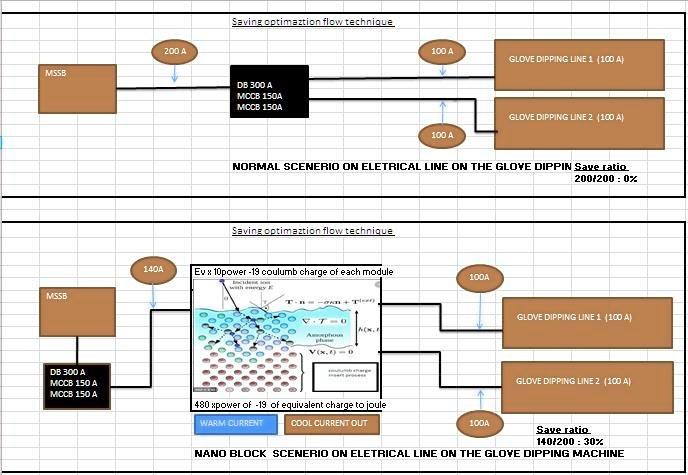

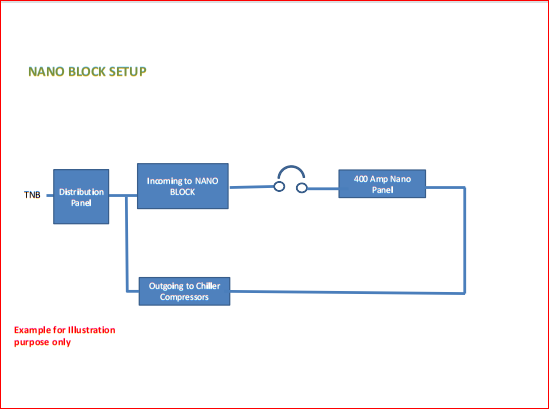

BLOCK SETUP DIAGRAM

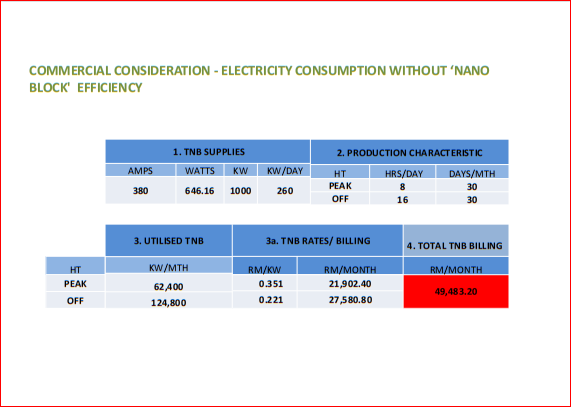

COMMERCIAL CONSIDERATION - ELECTRICITY CONSUMPTION WITHOUT ‘NANO BLOCK' EFFICIENCY 2. PRO

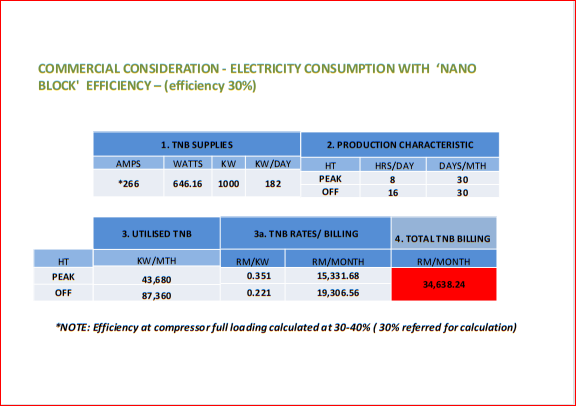

COMMERCIAL CONSIDERATION - ELECTRICITY CONSUMPTION WITH ‘NANO BLOCK' EFFICIENCY – (efficiency 30%)

COMMERCIAL CONSIDERATION - ELECTRICITY CONSUMPTION WITH ‘NANO BLOCK' EFFICIENCY – (efficiency 40%)

ROI CALCULATION (30 % Efficiency During Chiller Compressor Loading)

ROI CALCULATION (40 % Efficiency During Chiller Compressor Loading)

Terms and Conditions

- The 30-40% Efficiency onAmps reduction based on chiller compressor loading

- The 30-40% Efficiency onAmps reduction based on single line diagram.

- The Installations and Commissioning must be done by Mayura Engineering & Consultancy Sdn Bhd.

- The warranty for electrical items such Capacitor bank, Controller, MCCB and Contactor given 1 year warranty.

- The Nano Block Minerals given 5 years warranty. Subsequently 3 years maintenance at minimum cost required for inspection.

Summary/Conclusion

- The ideal solutions would be one 400 Amps Nano Panel based on data received for air compressor equipment .

- The Cost of panel estimated RM 400,000.00 for air compressor equipment (will be finalized after site visit)

- The ROI for the preliminary proposal would be 27 months based on 30% efficiency during chiller compressor loading and 20 months based on 40% efficiency during chiller compressor loading.

- The costing for installation of cable works not included in this proposal, however we will work at our best way to absorb the cost as much possible after site visit.

- Suggestion on panel installation can be placed beside DB Box

- Payment Option been given from Mayura Engineering & Consultancy Sdn Bhd